The End of the Line: How Water Scarcity Cannot Be Addressed Without a Circular Economy

Solving the water scarcity problem requires a circular economy. But what is the circular economy – and how can investors build it?

AUGUST 2022

Introduction

Responsible investing is heavy with buzzwords and acronyms: ESG, SDGs and more. But in a world liberally scattered with jargon, what are we to make of a recently popular concept – the circular economy? And why should investors join us in regarding it as an important principle around which to build our portfolios?

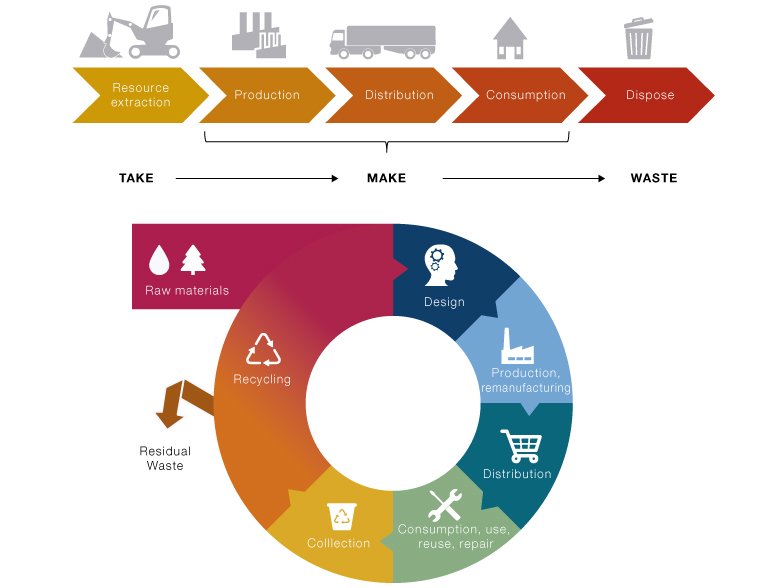

The circular economy is an attempt to close the linear consumption model of resource extraction, use, and then waste.

In short, the circular economy is an attempt to close the linear consumption model of resource extraction, use, and then waste. Take, for instance, paper. In a linear economy, a tree grows, is cut down and then is pulped to make paper which is then used. Once used, the paper is binned, completing a linear journey from seedling to landfill. However, in a circular economy, the used paper would be recycled up to seven times before finally being sent to a waste-energy plant – ‘circulating’ many times around the economy to maximise the uses of a single item, with the overarching aim of reducing mankind’s impact on the planet. Instead of being confined to a single product, the circular economy tries to apply this principle to as many products and commodities as is practically feasible. By working to make the global economy as circular as possible to reduce waste and minimise extraction, companies and investors can minimise their impact on the environment, and safeguard the planet for future generations.

Figure 1. Linear Versus Circular Economy

Source: Man Group. For illustrative purposes.

How Does This Work in Practice – and Relate To Water?

But as portfolio managers, how does the circular economy – laudable though its aims may be – connect to our work of investing in water?

Without circularity, clean water resources will continue to be reduced and contaminated.

The first point to note is that the extraction of resources for new products is deeply damaging to the environment – and contains grave threats to clean water supply. Containing the toxic fallout of processes such as mining, oil drilling and manufacturing is difficult. Tailings dams burst, oil wells leak and companies regularly dump toxic waste into rivers. Containment also does not account for the demands of such industries for large supplies of clean water as a basic necessity of their business model. In most cases, recycling entails a lower quantity of water use compared to virgin material production. The circular economy is therefore inseparable from the goal of sustainably managing and protecting Earth’s water supplies – without circularity, clean water resources will continue to be reduced and contaminated.

Fortunately, we see a great deal of innovation when it comes to reducing the impact of consumption on the environment. The circular economy is defined by the four ‘R’s’: reduce, reuse, recycle, and replace (Figure 2).

Figure 2. The Four R’s – Reduce, Reuse, Recycle, Replace

Source: Man GLG. For illustrative purposes.

In terms of reducing the amount of material needed to satisfy the world’s consumption demands, there has already been great progress – even if more is required. The mining industry is a clear example of how applying circular economy principles can aid the cause of water conservation. A standout area has been the growing use of dry separation techniques in mining to reduce freshwater consumption. These range from dry comminution, where ore is crushed and ground down to particle size without water being added, to non-aqueous processing techniques using polymers instead of water to separate ore particles from waste rock. Tailings, the often-toxic detritus left over after mineral has been fully separated from waste rock, are usually mixed with water and contained by a dam. However, by introducing course particle flotation techniques and dry stacking, miners are able to remove the water from residual waste, producing dry, stackable tailings. This provides safety benefits – lax safety precautions led to the collapse of a tailings dam in Brazil in 2019 which left 259 dead and 11 unaccounted for – by drastically reducing the amount of water needed for tailings storage1. Water usage can be further reduced by introducing water treatment facilities, aiming for a ‘closed loop’ system in which water usage is reduced, and the remainder is cleaned before being reused.

If a broader range of materials can be reused and brought within the purview of the circular economy, pressure on the environment can be reduced.

Reusing material is also a key principle of the circular economy. If a broader range of materials can be reused and brought within the purview of the circular economy, pressure on the environment can be reduced. A prime example is cement production, which is responsible for an estimated 8% of global carbon emissions2, with the final product often used to create concrete. It is possible to reuse waste concrete, with some 60-70% of the material reused, often as crushed hardcore in road building. However, new techniques have enabled concrete to be recycled fully, by mixing carbon dioxide with chemical additives to break down the concrete into its constituent elements. These can then be used to create new concrete, saving major environmental damage from new resource extraction.

Increasing the use of recycled materials within the production cycle is a similar, though equally important, part of the green transition. Steel production accounts for around 7% of global CO2 emissions and aluminium represents around 3%3. However, scrap-based steel can be made with up to 79% lower emissions intensity per ton, using an electric arc furnace compared with a traditional blast furnace process. Blast furnaces currently account for more than 70% of furnaces in use globally, and use entirely virgin iron ore to produce steel, leaving a great deal of room for improvement. Using recycled metal instead of virgin ores reduces water pollution by 76% and water use by 40%4. While capital intensity is a challenge – installing electric arc furnaces is not cheap – steel has many useful properties which make it ideal for recycling. It is magnetic, allowing for easy separation from other materials, and is robust enough to retain most of its useful properties throughout the recycling process. In short, recycled steel is an ideal candidate to replace new steel in much of our daily usage. Better yet, there is an additional step to approach full circularity. Even the production of recycled steel creates toxic dust as a by-product, which needs to be collected and stored safely. At present, dumping practices are still common in the industry and have a severe impact on the environment and human health as the toxic components are washed into the soil polluting groundwater reserves. However, it is possible to recycle and treat the steel dust itself, and to recover and reintroduce valuable materials into the market, with the residual steel slag used in the cement industry and for road construction. If we can see full circularity within the steel industry, it will go some way reducing the strain on our ecosystems and freshwater resources, as well as reducing the industry’s carbon footprint.

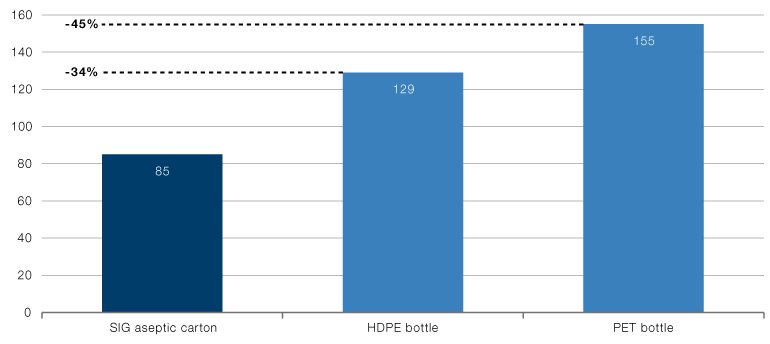

As well as recycling as many materials as possible, replacing those materials which are worst for water conservation and the wider environment is a key pillar in a fully circular economy. This will not be practicable for every material, but the fact remains that there are multiple instances where direct substitutes exist for every day pollutants. An example which relates to water would be plastic packaging. According to the United Nations, over 14 million tons of plastic end up in the ocean every year and just under 15% of plastics are currently recycled5. One solution would be to adopt the principles of the circular economy by replacing non-biodegradable plastics with carton packaging. This would not only mean a higher percentage of the packaging could be recycled – as stated above, carton and paper based products can be pulped and recycled many times – but it also would mean a reduced carbon footprint. Compared to HDPE or PET type plastic bottles, carton-based packaging requires 34% and 45% less carbon emissions to produce, respectively (Figure 3), as well as diverting a considerable amount of plastic from ending up in the ocean.

Figure 3. Carbon Life-Cycle – Carton Versus HDPE and PET Plastic Bottle

Source: LCA analysis, European average (EU27)/IFEU Institute Heidelberg using ISO 14040 international standard. For Illustrative Purposes Only.

These are just a few examples of how the principles of the circular economy can reduce the pressure of demand and consumption on the environment. However, moving towards a fully circular economy and protect water resources requires companies not only to innovate, but to design products in a way which allows for them to be easily reused or recycled. In “The Circular Economy Handbook” Lacy et al use the example of a cleaning spray bottle, in which the individual components are theoretically reusable or recyclable6. However, the metal spring, the plastic nozzle and the plastic bottle itself are all attached to each other, and require very different processes to recycle. This makes it unfeasible to actually recycle any of the components, as the effort required to disassemble the bottle is too high to make economic sense. However, with better design – for instance, making the entire bottle out of the same polymer to enable easy recycling, or designing the bottle for easy disassembly – circularity might become feasible and cost effective. In this way we need companies to work with design engineers and specialists across several fields to ensure that promises of improved sustainability do not prove hollow. That being said, while we recognise that far more work needs to be done, it is nevertheless encouraging to see how some of the highest-polluting industries are taking steps to reduce their impact.

The Circular Economy: A Portfolio Perspective

Many companies are under renewed pressure to improve the environmental impact of their business, with the circular economy further contributing to an existing trend of environmental consciousness. With more and more discussion around sustainability and water, how can discretionary managers best engage with the growing attention being paid to the circular economy, and do so in a way which enhances their portfolio?

The key thing, in our view, is to buy the solution providers.

The key thing, in our view, is to buy the solution providers. Most listed firms are already under pressure to reduce their environmental footprint, publishing climate targets as well as changing their energy providers and component sourcing to comply with the scrutiny of a more environmentally conscious consumer. However, this cannot happen overnight, and many companies lack the expertise and technical ability both to monitor their environmental impacts, and to address them. In addition, while many firms will wish to use recycled materials to meet environmental targets, most of them will have no desire to bring the recycling process in house.

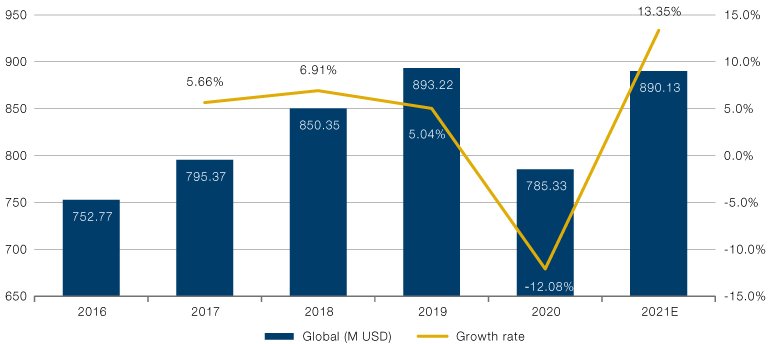

We therefore see alpha in three key areas. First, we are positive on waste disposal and recycling firms themselves. UN Sustainable Development Goal 12 specifically encourages large multi-nationals to adopt sustainable practices, meaning a growing potential customer base as firms seek to make their products recyclable. Before the pandemic, global sales of recycling equipment achieved a steady growth rate of 5-7% annually (Figure 4). As demand for recycled products increases, we feel that this may become a full secular shift, with further rapid growth for the sector, supporting waste management and recycling companies. Within this broad parameter, we would single out those firms with strong R&D capabilities as being ones to monitor: innovation is key to being able to profitably recycle a wider variety of materials, and provides an ongoing competitive advantage.

Figure 4. Global Recycling Equipment Revenue and Growth Rate

Source: Maia Research; as of 31 December 2021.

As the old saying goes, if you can’t measure it, you can’t manage it. If firms are to hit ambitious environmental targets, they will need improved data, simulation and monitoring services.

Second, we believe that there is likely to be concurrent earnings growth for firms that provide consultancy and information services regarding product design, recycling and water & waste management. As the old saying goes, if you can’t measure it, you can’t manage it. If firms are to hit ambitious environmental targets, they will need improved data, simulation and monitoring services, in regards to their manufacturing process, their immediate product range and their supply chains.

Third, we see particular value in specialist solutions companies exposed to highly polluting industries. By this, we mean firms that are able to solve technical, industry-specific environmental problems. Most often, the client base for these firms is in highly polluting industries such as mining, heavy industry, ICT, fashion or packaging. If firms are able to develop solutions to allow a wider range of materials to be recycled or to drastically reduce the amount of virgin commodities needed for production, then demand for their product – even if they do not control the recycling process themselves – is likely to benefit from the secular shifts currently underway.

We therefore feel that companies which are able to take circular economy principles onboard and apply them to their business models will experience stronger earnings and improved brand awareness as well as improve their environmental performance and water conservation.

Conclusion

Engaging with the principles of the circular economy is a key way in which investors can improve the sustainability of their portfolios and help to drive positive change. In multiple industries, innovation is allowing a wider variety of materials and products to be reused and recycled, to the ultimate benefit not only of the environment but also the society as a whole.

By selecting the companies responsible for this innovation – in recycling, analysis, data, and providing specialist solutions –investors have the opportunity to own the companies with a competitive advantage, which offer disruptive solutions and are at the forefront of the much needed transformation of the current economic system. Likewise, the circular economy is inseparable from the need to protect the Earth’s water supplies. As investors engage with the principles of circularity, they not only enhance their portfolios, but make a meaningful contribution to improving the conservation of clean water. The future belongs to those companies creating circular value – and investors should take note.